Marching Band

We Are Family

While the Chargers marching band has grown dramatically over the past decade, its devoted musicians — now 270 strong — have formed a powerful bond.

ALUMNI MAGAZINE

Wall installations, paper polyhedra, and re-contextualized vinyl. Just another day at the Makerspace.

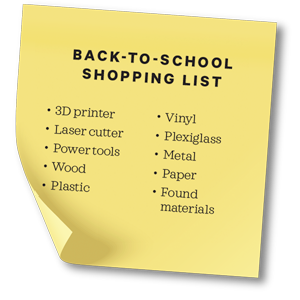

Aspiring artists sit next to students majoring in cellular and molecular biology and computer science. You are just as likely to be surrounded by scrap metal and sawdust as you are to be taking notes. And the final exam is far from standardized.

This fall, the College of Arts and Sciences at the University of New Haven launched a new B.F.A. program in Digital Art and Design. Digital Fabrication, one of the first courses to be offered as part of this new B.F.A., had its inaugural run last spring.

Digital Fabrication was the brainchild of Guy-Serge Emmanuel, M.F.A., assistant professor, and Joe Smolinski, senior lecturer, both in the Department of Art and Design. Emmanuel and Smolinski both saw the need for students across all disciplines to look more closely at the intersection of technology and fabrication — the action or process of manufacturing or inventing something. So they collaborated to design a course which drew students from a range of programs, including Art, Graphic Design, Engineering, Interior Design, and Molecular Biology.

"Across the country and across the nation, startups and shared tech spaces are on the rise. It’s important to expose students to these groups and environments as a complement to the Makerspace."Joe Smolinski, M.F.A.

Smolinski, who taught the first course, explains it this way: "Technology is a tool — not a means to an end creatively — so you need to think critically about how it is best utilized."

It’s a hands-on, lecture-based course. Some days might be spent sketching concepts, others designing projects on computers with 2D vector-based programs, digital photography software, and 3D modeling programs. Students were encouraged to fail early and often, prototyping by using a variety of methods in cutting, forming, printing, and shaping. They critiqued and, with Smolinski’s guidance, often went back to the technological drawing board. "They needed to learn the basic technical language, convert this idea and digitize it, and then bring it to life," Smolinski says.

"What we are doing is unique in that we offer everything from a focus that is completely digital, to fabrication, to virtual reality."Joe Smolinski, M.F.A.

The students found a home in the University of New Haven’s Makerspace to do just that. Located in the Tagliatela College of Engineering on the University’s main campus in West Haven, the space includes a variety of high-tech equipment, such as 3D printers and milling and edging machines, in addition to old-school tools such as hammers, screwdrivers, and pliers. In this setting, students are freed from the constraints of a more traditional lecture hall and can, as one student says, "get messy."

Maria-Isabel Carnasciali, Ph.D., an associate professor of Mechanical Engineering, charged with designing and equipping the Makerspace, worked closely with Smolinski to make sure the students could take full advantage of what it had to offer. Ultimately, the space will be housed in the University’s cornerstone building project, the new Bergami Center for Science, Technology, and Innovation, which broke ground this fall.

Smolinski also wanted his students to connect with the larger West Haven community, so he reached out to J.R. Logan, the "Chief Maker" at MakeHaven on Chapel Street in New Haven. MakeHaven is a 4,000-square-foot, not-for-profit gathering place and workshop for, according to its website, "makers, creators, tinkerers, and dreamers." Projects in this space include mechanics, electronics, crafts, digital art, biology, and woodworking. As such, it was the perfect complement to the students’ oncampus experience at the University Makerspace.

"Technology is a tool — not a means to an end creatively — so you need to think critically about how it is best utilized."Joe Smolinski, M.F.A.

"This course wasn’t only about fabrication," Smolinski says. "It was about connecting with other people and finding mentors to help brainstorm and troubleshoot. Across the country and across the nation, startups and shared tech spaces are on the rise. It’s important to expose students to these groups and environments as a complement to the Makerspace. They need to know how to find and connect with these communities."

Students in the class displayed their final projects at an event at MakeHaven near the end of the spring semester. Among the projects: a laser-cut modernist lamp, an eight-color vinyl portrait, and a 3D printed cell model.

Moving forward, Digital Fabrication will continue to be a major requirement for the B.F.A. in Digital Art and Design. "Other institutions offer digital art degrees," Smolinski says, "but what we are doing is unique in that we offer everything from a focus that is completely digital, to fabrication, to virtual reality. There are so many different ways to take steps into the world of digitization. And these kids make that happen."

While the Chargers marching band has grown dramatically over the past decade, its devoted musicians — now 270 strong — have formed a powerful bond.

Welcome to the newly established School of Health Sciences.

Former Chargers captain and current Board of Governors member Allen Love Jr. ’88, MPA ’90 lends a global perspective to the world of anti-money laundering.